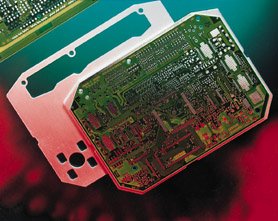

Fuba Printed Circuits developed a manufacturing process that enables the company to realize cost efficient and reliable heatsink solutions. The process of joining a metal plate with the PCB is integrated in the production line directly after board fabrication.

Alfred Wojtecki, Fuba Printed Circuits, Germany

The PCB production is steadily changing to a more sophisticated process and requires a level of manufacturing knowledge that is constantly getting higher. It is necessary to adopt equipment and technology to the fast changing requirements and technological trends. The trend towards miniaturization continues unabated. The packaging density has increased rapidly in the past few years and will go on. The function density, speed and number of pins of ICs are constantly rising. The consequence of all of this is that PCBs have become highly packed high-power assemblies that require dissipation of the generated heat. For the large majority of applications, CIC, CAC, thermal pads, thermal vias, component heatsinks, wedgelocks with housing junctions or ventilators have been used until now. To some extent, these solutions result in inadequate or cost-intensive heat dissipation.

Fuba achieves optimal heat dissipation on PCBs, which are bonded with the help of an adhesive to an aluminium plate, for example. That plate then acts as a heatsink. The joining process followed by pressing, is integrated in the production process directly after board fabrication. This means that short cycle times can be realized in addition to high efficiency. The universal material properties enable the manufacturer to adapt the heatsink fabrication to the design methods and the thermal requirements. Consequently, the heatsink design can be conceived to fit in with the customers needs. An intensive support right from the design phase will be provided.

Properties of aluminium and adhesive

The combination of a PCB with an aluminium plate, for example, offers an optimal heat absorption. The manufacturing process enables the realization of any contour. The material thicknesses can vary, begining at 0.4mm. This heatsinks, combining a planar surface with light weight, are reflow solderable. Feature of the adhesive is a high insulation value as well as a good thermal conductivity. The adhesive provides high bond force and is resistant to heat. A flexible coefficient of thermal expansion allows the use with different base materials as well as different metals. Fax +49-5327-880-200

At Fuba, a great deal of investment is going into process engineering and product development. The previously scattered process engineers of the Gittelde plant that were assigned to production areas have been brought together in a central technology department and reinforced with extra staff. The domain of process engineering covers development, project management and the putting into practice of new processes and plant engineering. It supports production in finding suitable equipment and in optimizing existing production processes. Product development, which, in close collaboration with sales and process engineers, acts as a direct contact for customers, has also been expanded with more staff, and now comes under the umbrella of the technology department. Acting as a central connection point for customers‘ technical inquiries, it jointly works with the users to realize technologically innovative and processable products.

Der Leiterplattenhersteller Fuba Printed Circuits kann in der Serienfertigung die PCBs gleich mit einer Wärmesenke (Heatsink) versehen. Solche Leiterplatten bestehen aus dem üblichen Schaltungsträger, auf den mit einem besonderen Kleber und Druck eine Metallplatte fest aufgebracht wird. Diese Platinen sind in der Lage, besonders gut Verlustwärme abzuführen.

Le fabricant allemand de cartes imprimées Fuba Printed Circuits a développé et mis en service pour la fabrication en série, un procédé qui permet de réaliser des „Heatsinks“. Ces cartes imprimées se composent du support du circuit proprement dit, qui est pressé sur une plaque métallique à l’aide d’une colle particulière. Les cartes de ce type conviennent pour la réalisation de modules nécessitant l’évacuation d’une quantité importante de chaleur dissipée.

Il produttore tedesco di conduttori metallici Fuba Printed Circuits, ha sviluppato un processo che ha introdotto nella produzione di serie il cui aiuto permette la costruzione dei cosiddetti Heatssinks. Questi conduttori metallici consistono di un proprio portainterruttore, che con l’aiuto di una colla speciale si può premere su di una piastra metallica. Piastrine di questo tipo, si adattano per gruppi di costruzione da cui si deve considerare una perdita di calore.

EPP 211

Unsere Webinar-Empfehlung

SAKI is a Japanese supplier of SPI, AOI, AXI, THD and coating inspection solutions as an all-in-one hardware and software platform.

Teilen: