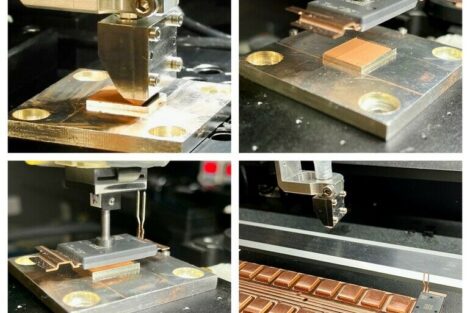

Traditionally, RFI shielding cans are hard-soldered to PCBs during assembly, making rework an expensive and time-consuming process. Many applications require components to be “tuned” prior to the shields being fitted, thus adding an expensive manual solder operation to the final cost. Harwin now offers the surface mount RFI Shield Clip as a simple solution to address these issues. The clip allows the shielding cans to be fitted and removed several times, allowing rework or tuning, if required with no degradation in performance or risk of damage. The clips are supplied in EIA standard tape and reel packaging and can be placed onto the boards with any placement machine. The clips are fitted during the assembly process and soldered as any other part with the clip self-centering during reflow on the pad. This eliminates the additional expense of secondary hand placement soldering operations and ensures optimal alignment. Once the clip is placed and soldered, the shielding can then be fitted into the spring contacts.

EPP 217

Unsere Webinar-Empfehlung

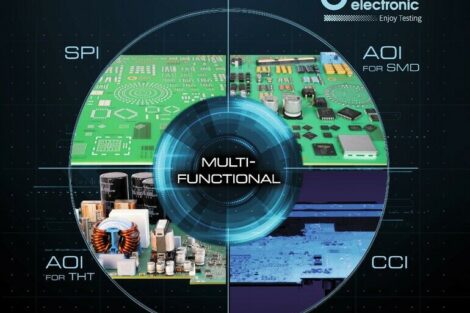

Die Nutzung der 3D-Mess- und Prozessdaten bringt die Produktionssteuerung auf die nächste Stufe. Echte 3D-Messung ermöglicht KI-basierte Prozessmodellierung zur Vorhersage von Parameteränderungen und -defekten oder zur Ursachenanalyse bis hin zu einzelnen Werkzeugen und Best…

Teilen: