The Walter Grandjot Test- and Measurement Services has introduced a flying prober mechanism as add-on to an existing in-circuit test system. The concept is to use as much as possible elements of the standard equipment for this solution.

Walter Grandjot, Test & MesstechnikServices, Herrenberg, Germany

The German service company Grandjot, an Agilent partner, is focused on test programming for board test systems of the Agilent 3070 family. The idea was born when this Agilent partner saw at customer’s sites flying probers working near by the in-circuit tester. Because many units of both machines are of the same functionality – why not combine them?

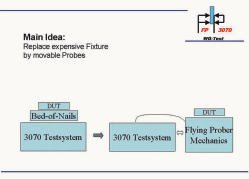

For this reason, flying prober equipment was developed as an add-on to the 3070 system. The main idea behind was to use as much as possible functionality of the 3070 standard features (hardware and software), but replacing the expensive fixture by movable probes. To begin with the procedure, the user generates a normal in-circuit test program (ICT). But instead of sending the fixture files to the fixture builder, they are used in some post-processing software to extract the flying-prober commands. Take a resistor measurement for example: instead of selecting two probes out of several hundreds on a fixture by a relay switch matrix, two probes are moved to the position of the testpads. This combination makes an ideal solution for the electrical test of prototypes and low-volume boards.

The precise and fast moving probe mechanism was engineered and manufactured in co-operation with the specialist company IEF-Werner in Furtwangen, Germany. They have a lot of experience with critical equipment for accurate moving and positioning in the area of electronics production. The mechanics is based on a standard 2D linear motor table, controlled by standard motor drivers. The probes are standard pneumatic pointing devices from Ingun.

The board test system will be delivered by Agilent, or mostly taken from an existing one on the shop floor. The programming follows the standard rules of a 3070 ICT-program generation. Special software was developed which extracts the XY data from the standard fixture files and controls the probe movements. The 3070-ASRU unit does all measurements, and the debug environment is the 3070 standard.

This concept of using standards and available and reliable software and hardware wherever possible results in a stable machine at low cost of development and building.

The flying prober add-on to the 3070-test system provides several advantages:

• Time saving – instead of waiting one month for the fixture, it takes only one day to generate a program

• Fixture cost saving – prototypes and low-volume boards can be tested without an expensive fixture

• Investment saving – since most of the test system functionality can be used, the price of the add-on gear is less than half the price of a stand-alone flying prober

• User training – software development and operation are following the 3070 standard – so every user can handle the system

It is planned to use the FP3070 as in-circuit test system, as far as four probes are sufficient. That is sufficient for the verification of shorts and for an analog ICT. In a future revision the FP3070 could be used for boundary-scan test, TestJet solutions or the functional verification of simple logic devices. The required test hardware is provided with the 3070 system; its functionality has just to be included into the FP3070 software. Expanding possibilities exist by software updates.

EPP 195

Zusammenfassung

In den Prüffeldern vieler Elektronikhersteller wird oft parallel eine Reihe unterschiedlicher Testsysteme betrieben, deren Anwendung sich sinnvoll ergänzt. Nehmen wir zum Beispiel In-Circuit-Tester und Flying-Probe. Mit einer zusätzlichen Mechanik, die statt des üblichen Nadelbettadapters am System angeschlossen wird, können Agilents Boardtester der Serie 3070 so-zusagen im Handumdrehen zu Flying-Probern umge-rüstet werden.

Résumé

Une série de systèmes de test complémentaires différents est souvent utilisée en parallèle dans les bancs d’essai de nombreux fabricants d’électronique. Prenons par exemple le In-Circuit-Tester et Flying-Probe. Avec une mécanique supplémentaire qui se raccorde au système à la place de l’adaptateur planche à clous habituel, il devient possible de transformer pour ainsi dire en un tournemain les Agilents Boardtester de la série 3070 en Flying-Prober.

Sommario

Nei settori di controllo di molti produttori di componenti elettronici viene utilizzata speso in maniera parallela una larga serie di sistemi di controllo che si implementano l’uno con l’altro. Consideriamo per esempio In-Circuit-Tester e Flying-Probe. Con un dispositivo meccanico supplementare che viene collegato al sistema al posto del classico adattatore per basamento ad aghi, è possibile trasformare in un attimo degli Agilents Boardstester della serie 3070 in Flying Prober.

Unsere Webinar-Empfehlung

Conformal Coating ist ein wichtiges Verfahren, um elektronische Baugruppen vor dem vorzeitigen Ausfall zu schützen. Damit bekommt der Beschichtungsprozess eine immer höhere Bedeutung. Dabei ist die Auftragsstärke ein wichtiges Qualitätskriterium. Nur eine zeitnahe schnelle Messung…

Teilen:

.png)