Valor is driving internet-based work group collaboration for electronics manufacturers a step further. Up to now, the company had made itself a name with integrated software solutions for DFM (design for manufacturing) and CAM, which aim at integrating the production-oriented value chains of OEMs and CEMs.

Now, with the spin-off of e4eNet.com, headquartered in Waltham/Boston, Massachusetts, Valor inaugurates a highly structured, holistic approach to the electronics manufacturing supply chain: R&D, engineering, procurement, production, delivery, sales and quality assurance. The spin-off will establish a global co-operation network between distributed design and engineering groups and their suppliers and customers. It enables the networking of the entire supply chain via the Internet, through a host of software services that can be subscribed to and accessed through standard web browsers.

The e4eNet supply-chain networking platform offers broadband access and a host of multifunctional production services – independent of the geographical locations or time zones of its participating members. It aims at shortening the time-to-market period by eliminating delays that are caused by the sequential nature ofinformation flows betweenthe various steps of manufacturing and the corporate re-view and approval process, in which various suppliers participate.

Solving thecommunication case

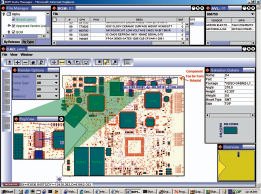

With e4eNet, all members of a supply chain communicate and collaborate efficiently and securely by establishing a virtual project space for exchanging and updating product and engineering data within a given production chain in real time. The ‘e-collaboration’ B2B platform offers a variety of specific engineering functions via the web: project management, tracking of materials and components, video and VoIP. This allows for storing and modifying product data and administering them on enterprise servers. It also allows to conduct live meetings via video and voice. Existing CAD, PDM and ERP (enterprise resource planning) solutions can be integrated in this process.

This service defines a shared and protected workspace for all admitted participants. ”The special aspect of e4eNet“, says Valor CEO Schmil Dolberg, ”is that it solves the communication dilemma of the electronics manufacturing industry by establishing a totally integrated network of servers, secure internet tools and powerful e-collaboration software for widely distributed supply chains“. By doing so, e4eNet offers not just a communication platform like the older groupware programs or internet-based peer-to-peer services. Apparently, it offers a functionality that is well-adapted to the complexity of electronics manufacturing. It guarantees – via ODB++(X) and XML-based APIs – an openarchitecture and conformity with the Rosetta standard. Encryption between servers is done with 630 bits, between servers and users with 128 bit.

As a ‘pure-play’ platform, e4eNet scales within and between corporations according to user demand. It also serves as a neutral collaboration environment and a protective ‘honest broker’ between any competing supply-chain members. Multi-site synchronization is available as a standard configuration. In off-line mode, the system offers access via laptop PC. Currently, the following services are available: production management, BOM and DFM data managers, panelization manager, mechanical data manager, application meeting manager, production checkpoint auditor, guideline administrator, product content manager, and data release manager. More are to come.

Also, Celestica announced a beta agreement with e4eNet for the development of B2B collaboration technologies for engineering services. This re-enforces and expands the existing working relationship between Valor and Celestica, says Celestica VP of corporate technology, John Yealland. ”Celestica has decided to use Valor’s ODB++ based software for its engineering activities worldwide.“ (Werner Schulz)

EPP 204

Unsere Webinar-Empfehlung

Auch dieses Jahr präsentiert Koh Young wieder aktuelle Trends und „State of the Art“ Technologie aus der optischen Inspektion und 3D-Messung auf der Productronica in München. Aber wir alle kennen das Problem voller Terminkalender, Reisebeschränkungen oder fehlender Zeit, um in…

Teilen:

.png)